.png)

|

|

Services

|

Precision Machining (CNC)

|

|

|

|

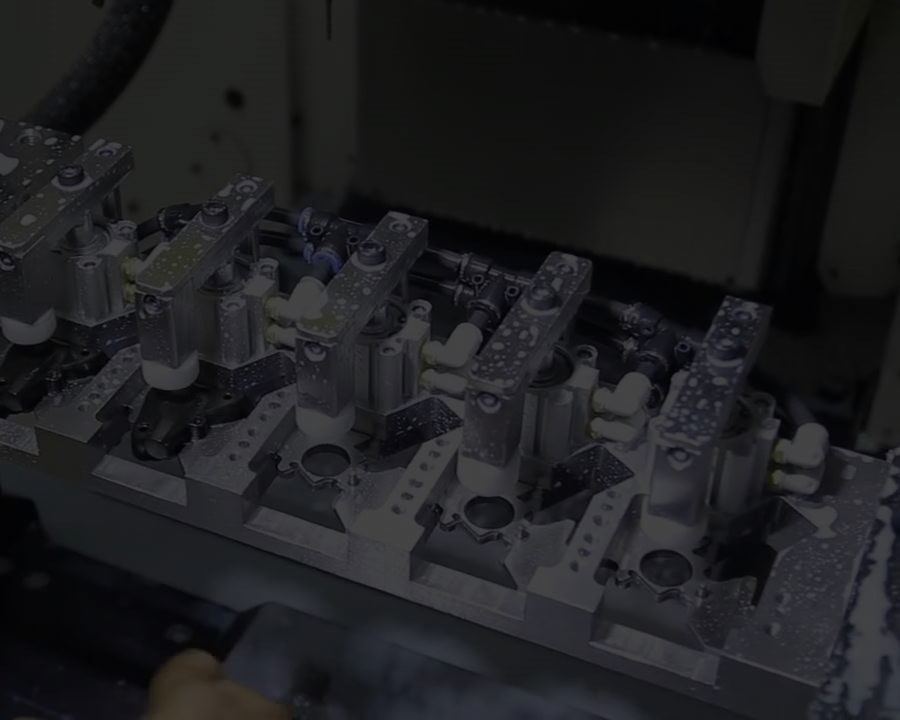

| Precision, quality, and innovation – these are the hallmarks of Local Holdings. As a leader in advanced manufacturing, we are committed to exceeding your expectations and delivering flawless products to enhance your success.

|

|

|

| We operate over 400 high-precision CNC machines, including Turning, Milling, and Auto Lather to fulfil your manufacturing needs.

|

|

|

|

|

|

|

Quality Control

|

|

|

|

|

To ensure exceptional quality in our precision machining processes,

we employ advanced quality control measures using cutting-edge equipment:

|

|

|

Future Ready Industry 4.0

|

|

|

|

|

| Our precision manufacturing process is enhanced by our fully-digitised corporate infrastructure, incorporating Dynamic ERP software and production information (OEE), which streamline production and provide greater transparency. Additionally, we are committed to developing a future-ready Industry 4.0 infrastructure that includes automation, digitisation, big data, cloud computing, and AI to drive innovation and efficiency in our operations.

|

|

|

|

|

|

|

|

| Advanced tool break sensors

|

|

|

| These sensors detect potential tool failures or breakages, preventing costly downtime and ensuring uninterrupted production.

|

|

|

|

|

|

|

| Roundness Tester

|

|

|

| We use roundness testers to verify the circularity and concentricity of machined components.

|

|

|

|

|

|

|

| AI-based Vision Inspection Machines (VIM)

|

|

|

| Our investment in VIM guarantees that finished goods meet the most stringent quality requirements before they are shipped to you, ensuring your satisfaction.

|

|

|

|

|

|

|

|

| Tool presetters

|

|

|

| We utilise tool presetters to reduce labour intensity and save valuable time and costs when setting up equipment for new components.

|

|

|

|

|

|

|

| CMM (Coordinate Measuring Machine)

|

|

|

| This equipment ensures precise measurement and validation of dimensional accuracy.

|

|

|

|

|

|

|

| Real-time Statistical Process Control (SPC)

|

|

|

| Our SPC system monitors the quality of the fabrication process at every step, enabling us to identify and address any deviations from desired specifications to ensure consistent excellence.

|

|

|

|

|

|

|

|

| Roughness Tester

|

|

|

| Our roughness testers measure the surface finish of machined parts, ensuring they meet the required specifications.

|

|

|

|

|

|

|

| Compression Tester

|

|

|

| This equipment allows us to assess the compressive strength and performance of components.

|

|

|

|

|

|

|

| Imaging Scan Measurement

|

|

|

| An instant solution to conventional quality inspection problems. Perform high-precision measurements, automatically record data, and generate reports with the push of a button.

|

|

|

|

|

Ready to Discover More?

|

Inquire tailored strategies, support and find the

answers you seek today.

|

|

| Enquire Now

|

|

|

Embrace ESG for Sustainable Future!

|

Inquire tailored strategies, support and find the

answers you seek today.

|

|

| Read More

|

|

|

|

|

|

|

|

|

|

|